Integrated Plastic Molding Solutions

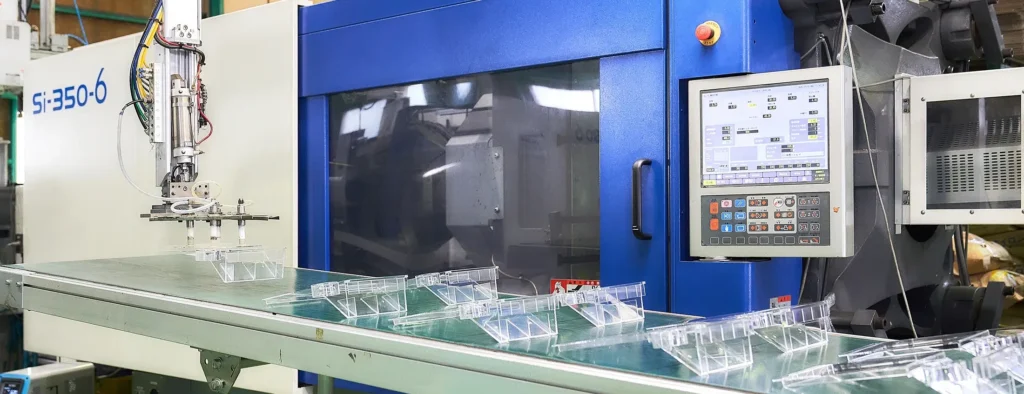

While our core focus is injection molding, we also handle vacuum forming, thermoset molding, and blow molding, and we support both small-lot and prototype production.

Our projects range from retail displays to aircraft interior parts, pneumatic equipment, and security or disaster-prevention components. We process challenging materials such as super engineering plastics, eco-friendly resins, and glass fiber–reinforced plastics.

From mold design to molding, finishing, and assembly, we provide integrated solutions tailored to each project.

Balancing Every Detail

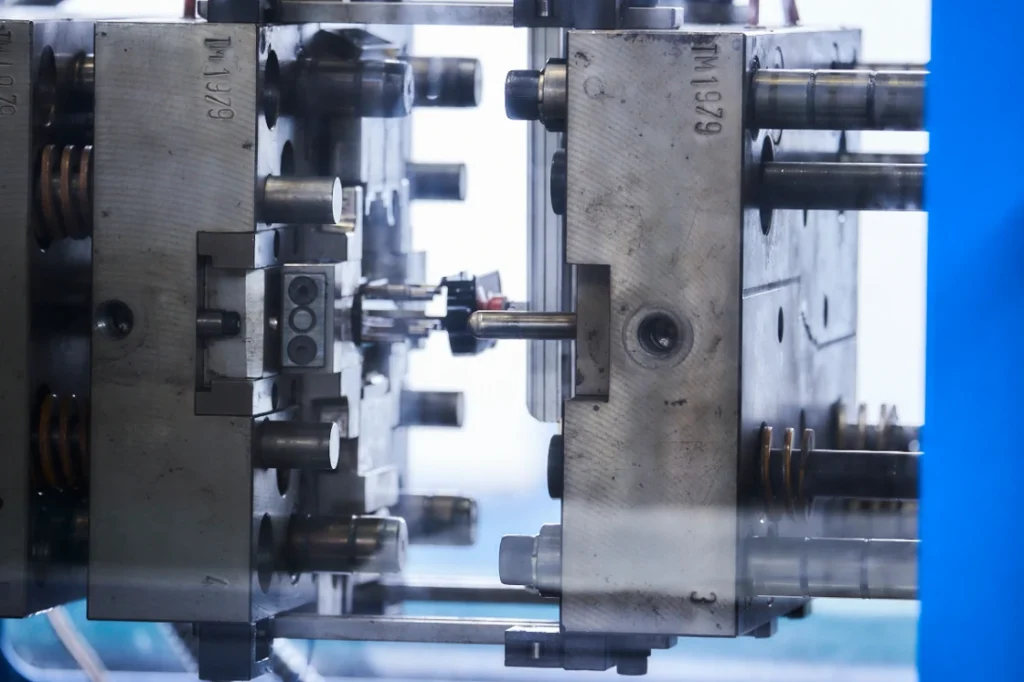

Injection molding requires the careful adjustment of numerous factors—such as material temperature, mold temperature, injection speed, pressure, and clamping force—through repeated trial runs. Even the smallest variation can greatly affect the final result.

While many cases are considered difficult to mold due to narrow process windows, we go a step further. Under strict quality control, we continually refine molding conditions to bring out the best in each material and product shape. By balancing temperature, pressure, and resin flow with precision, we achieve stable, high-quality mass production even under challenging conditions.

Taisei’s Strengths

01

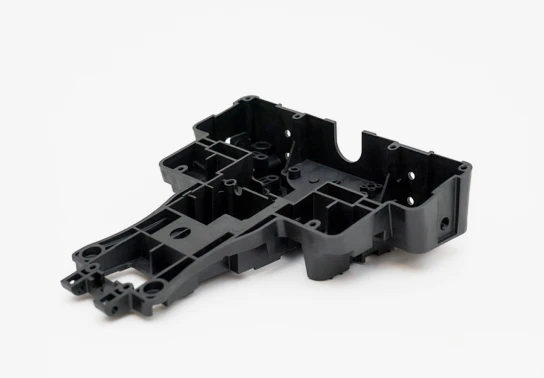

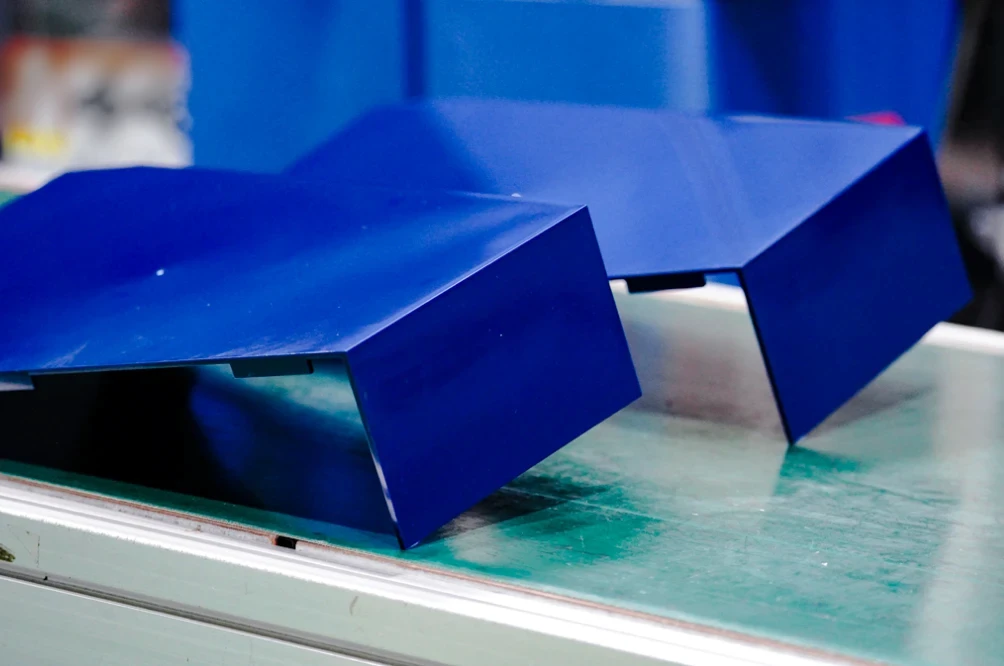

Reproducing Complex Geometries

Our engineers precisely control mold temperature, injection pressure, and cooling conditions to achieve optimal molding balance. Even with complex shapes or varying wall thicknesses, we ensure dimensional accuracy and surface quality for stable, high-precision results.

02

Crystal-Clear Molding

03

Precision Management

Made with flame-resistant resin that reduces smoke and odor.

Made with flame-resistant resin that reduces smoke and odor.

04

Molding High-Performance Materials

High-Performance Resins

Eco-Friendly Plastics

Reinforced Resins

Surface Finishing

Glass Fiber Resins (Japanese)

Eco Plastics (Japanese)

05

Support for Production and Mold Transfer

We flexibly accommodate production transfers from other manufacturers. By carefully inspecting the condition of existing molds and optimizing molding parameters, we ensure stable quality and dimensional accuracy after transfer.

Experienced engineers oversee every step of the startup process, enabling a smooth transition and rapid restart of mass production.

Note: This service is primarily available within Japan.

Industries We Serve

Taisei produces molded products for diverse industries, including displays, aircraft, housing equipment, and amusement devices. We also mold high-precision, durable parts for pneumatic, security, and disaster-prevention applications.

Through optimized processes and strict quality control, we deliver reliable manufacturing support across industries.

Displays

Aircraft Interiors

Housing Equipment

Amusement Devices

Pneumatic Equipment

- 株式会社タイセイ](https://taisei-i.com/wp-content/uploads/2025/10/220-1024x683.webp)

Safety & Security

- 株式会社タイセイ](https://taisei-i.com/wp-content/uploads/2025/10/213-1024x683.webp)

Industrial Parts

Equipment Overview

Molding Equipment

350t TOYO Si-350VI

×1

280t TOYO Si-280VI

×1

180t NISSEI NEX180

×1

180t NISSEI FN4000

×1

140t NISSEI NEX2000

×1

80t TOYO Si-80IV

×1

75t SUMITOMO SE75EV-A

×1

50t TOYO Si-50IV

×1

Auxiliary Equipment

Dehumidifying Dryer

×4

Chiller / Temperature Control Unit

×2

Mold Temperature Controller

×7

Mixer

×1

Hydraulic Unit

×2

3D Printer: MUTOH MF-2200D

×1

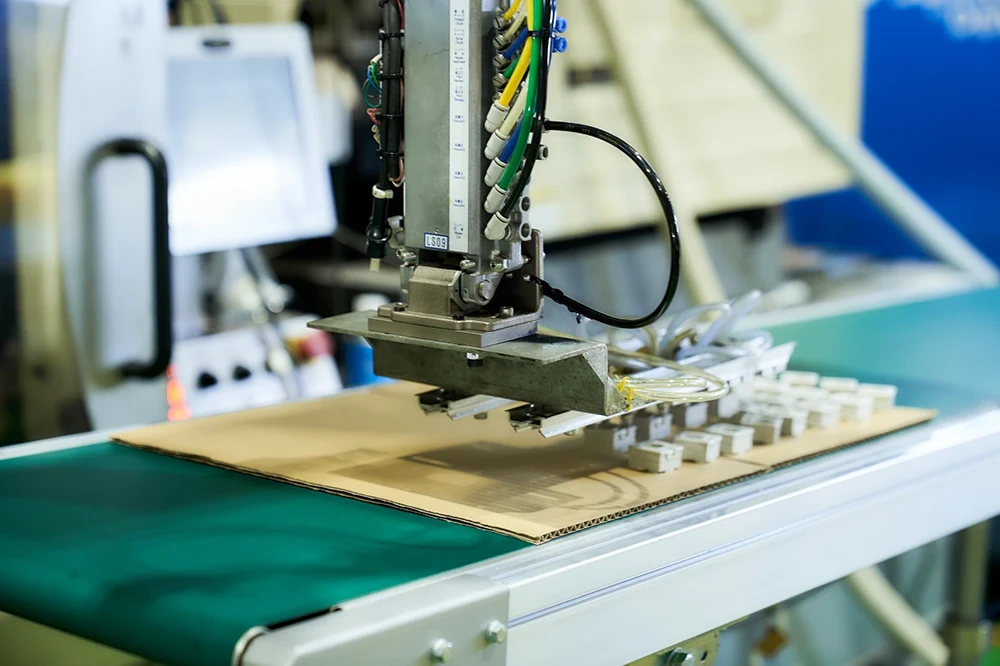

Stand-Type Ultrasonic Welder

×1

Si-350VI

SE75EV-A