Shaping Ideas with Precision

Japanese Quality, Global Trust

Taisei is a Japan-based plastic molding manufacturer

providing fully integrated solutions —

from mold design and production

to injection molding, secondary processing, and assembly.

With decades of expertise, we deliver genuine Japanese quality,

meeting the highest standards for complex shapes and materials.

Our flexible system supports both single processes and

end-to-end solutions — turning your ideas into precision-crafted reality.

1

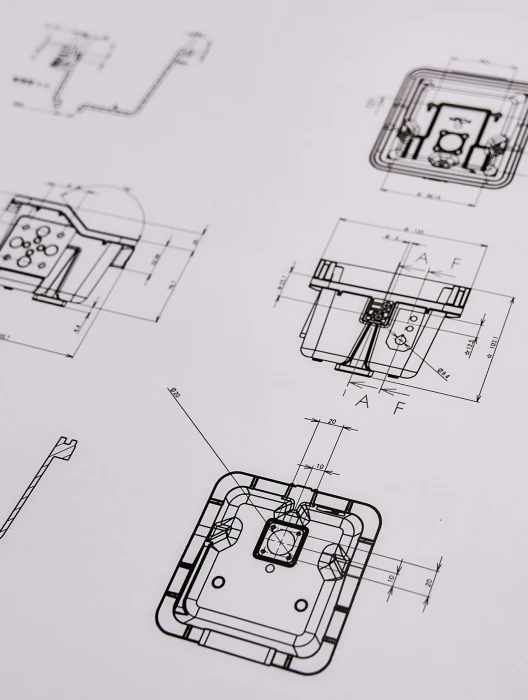

Product Engineering

2

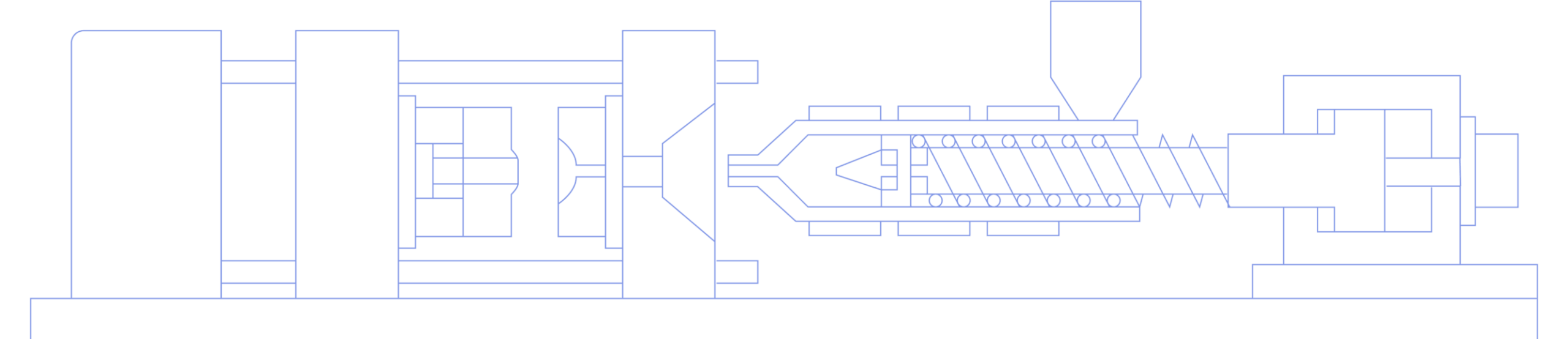

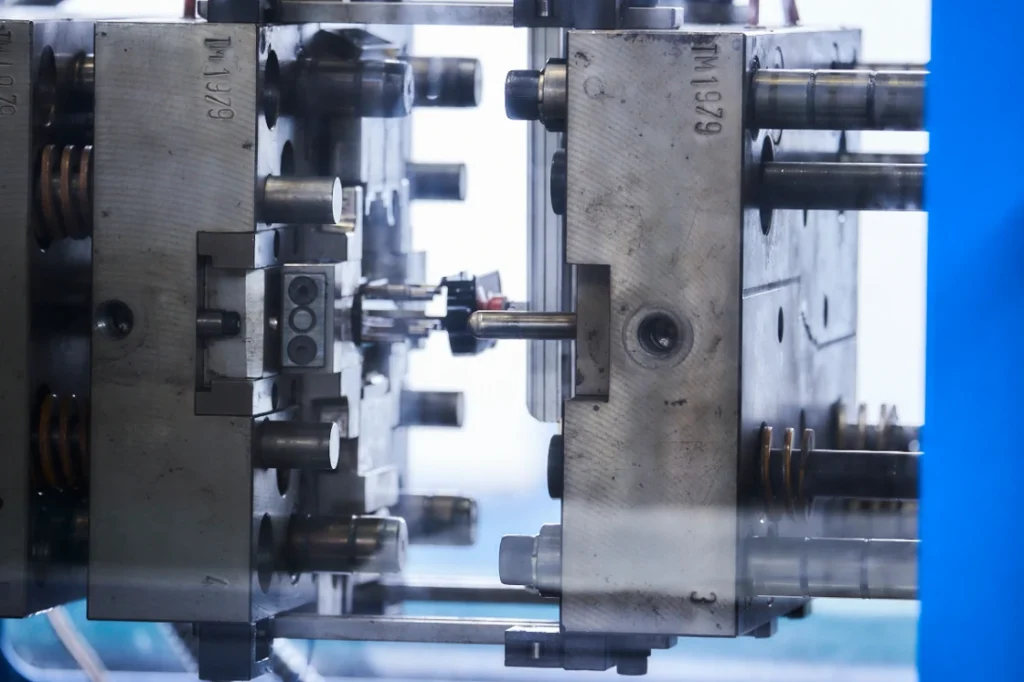

Mold Production

3

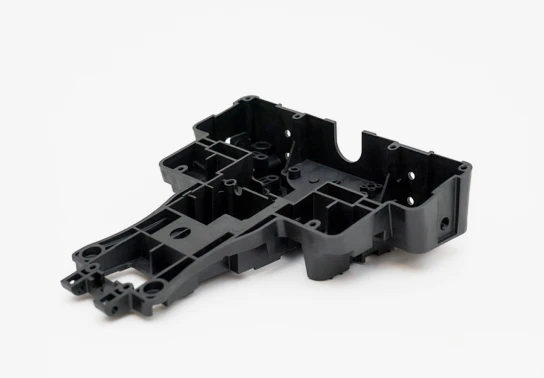

Injection Molding

4

Secondary Processing

Injection Molding

High-Precision, High-Quality Plastic Molding Powered by Expertise and Advanced Technology

Focused on injection molding, we also handle vacuum forming,

thermoset molding, and blow molding.

Our engineers carefully control temperature, pressure, and cooling to ensure optimal balance and consistent quality.

Taisei’s Plastic Molding

01

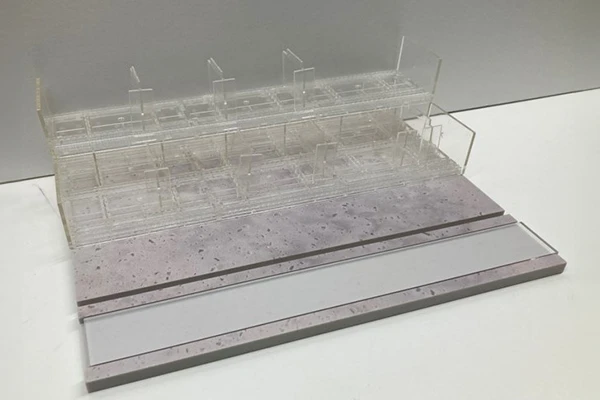

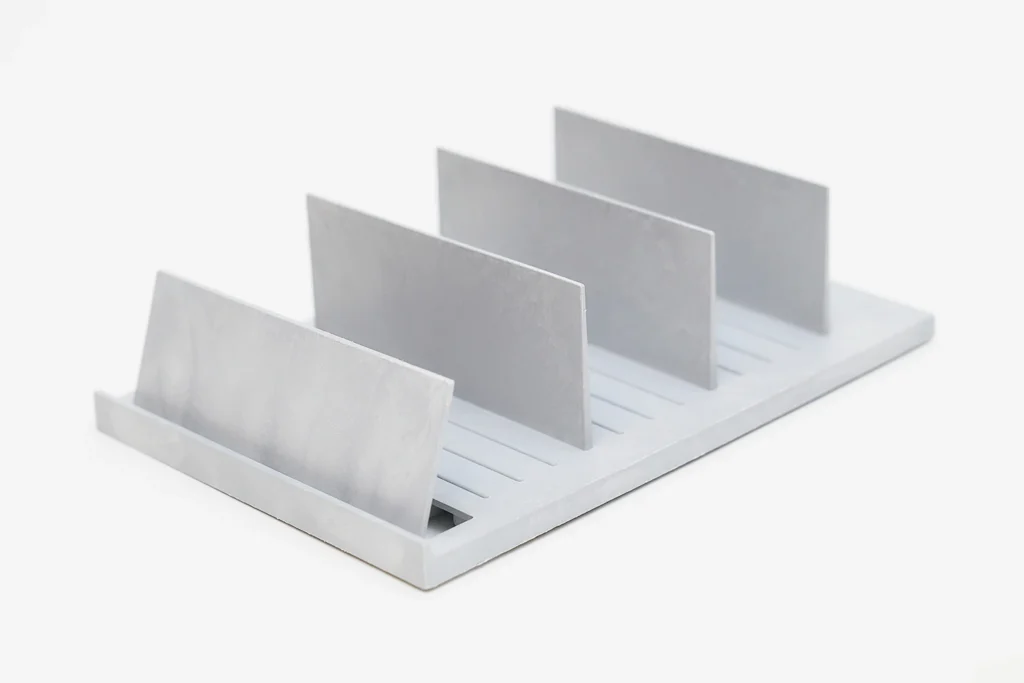

Complex Shapes

We achieve stable molding even under challenging conditions

and with varying wall thicknesses through precise process control.

02

Clear Molding

03

Precision Quality

04

Advanced Materials

High-Performance Resins

Reinforced Resins

Eco Plastics

05

Other Molding Methods

Showcase

Case studies with technical details (Japanese only)

Our showcase includes product photos along with information on application fields, molding methods, material categories, and applied technologies. Even though the page is in Japanese, the technical details and images help you understand our capabilities.

Product Engineering

Comprehensive Support from Prototyping to Mass Production

Mold Production

The Core of Plastic Molding

— Precision Built on Quality

Secondary Processing & Assembly

Comprehensive Finishing

— From Processing to Packaging

Toward World-Class Quality

JAPANESE QUALITY

With sincerity and a spirit of continual challenge, we carry trust and quality into the future.