Toward World-Class Quality

JAPAN QUALITY

With sincerity and a spirit of continuous innovation,

we carry trust and quality into the future.

We take pride in every product we create, embodying the craftsmanship that defines Japan. Through precision engineering, strict quality control, and attentive service, we pursue excellence worthy of global trust.

From mold design to final finishing, every process reflects our unwavering commitment to “Japan Quality” delivered in its purest form.

Through our work, we strive to enrich lives and help build a safer, more sustainable future.

Precision for Every Material

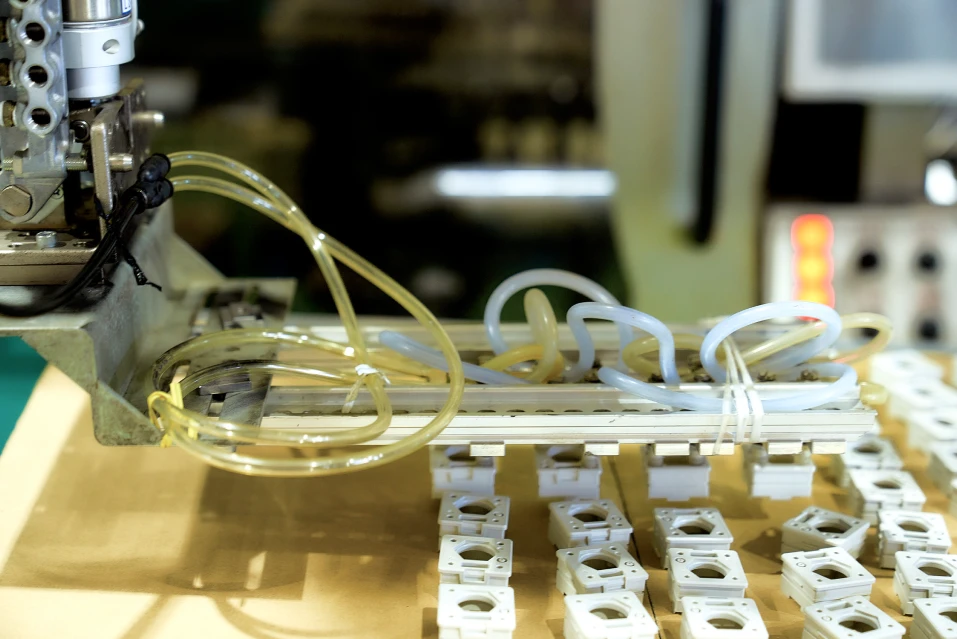

When working with challenging materials or complex shapes, we optimize design and molding conditions to achieve stable, repeatable quality in mass production. By mastering the properties of super engineering plastics, glass fiber–reinforced resins, and recycled materials, we deliver visual and dimensional precision — even for complex or transparent parts.

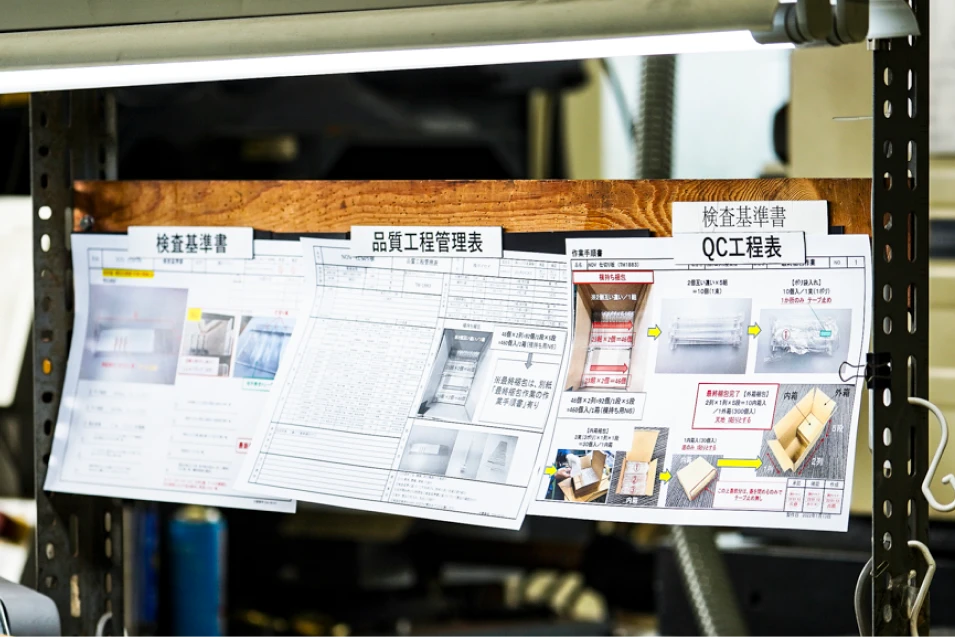

To ensure consistent quality, each process is standardized, recorded, and traceable. We maintain stability through mold monitoring and planned maintenance, while optimizing the entire flow — from molding to secondary processing — to minimize variation and improve efficiency.

Stringent quality standards are required in aircraft interior projects, and we manufacture our products to meet those exacting demands. Our pursuit of quality is a continual challenge that drives us forward.

Sustainable Molding Solutions

We place great importance on environmentally conscious manufacturing. Eco-friendly plastics — including recycled materials, biodegradable resins, and bio-based polymers — are vital to a sustainable society, though often difficult to process.

At Taisei, we apply our expertise to achieve stable, high-quality molding with these materials. By mastering challenging resins, we strive to balance environmental responsibility with exceptional product quality.

Sustainability and Business Continuity

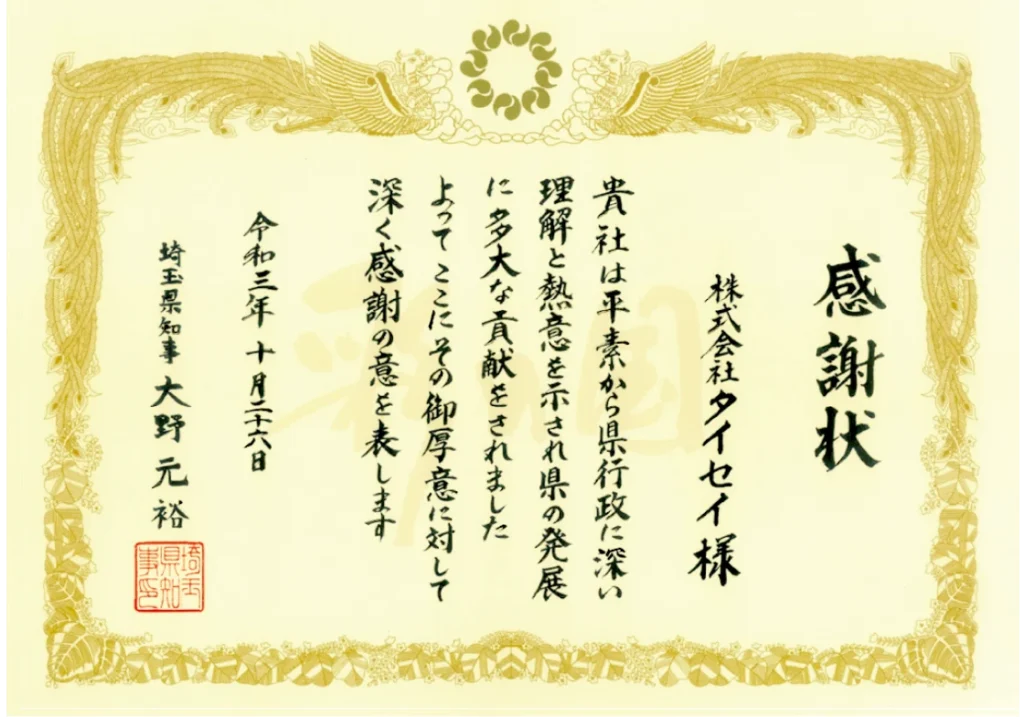

Through Saitama Resona Bank, we issued donation-based private bonds to support the local community. A portion of the proceeds was donated to environmental programs promoting plastic recycling, earning a letter of appreciation from the Governor of Saitama Prefecture.

Introduction of Solar Power and Battery Systems (2022)

As part of our BCP measures, solar panels were installed at the head office and Kazo plant. These systems enhance business continuity with backup power during outages and reduce energy costs and CO₂ emissions through on-site renewable energy use.

Our Journey

Founded in 1992, Taisei began as a manufacturer of plastic products built on the belief in “building trust through manufacturing.” Over time, we established an integrated system covering design, molding, and sales.

In the 2000s, we expanded mold production to South Korea and China, enhancing both cost efficiency and quality. With the Kazo Plant and ISO 9001 certification, our quality assurance system was further strengthened.

We have introduced advanced technologies such as injection molding, 3D printing, and ultrasonic welding, enabling the production of complex, high-precision parts. Through collaborations with government agencies and universities, we continue to expand the possibilities of manufacturing.

In 2022, Yuki Kumagami assumed the role of president, carrying forward the expertise and trust cultivated since our founding. Today, Taisei continues to advance molding technology through innovations such as 3D printing and ultrasonic welding, while embracing eco-friendly plastics to contribute to a sustainable future.

Supporting Local Industry

As population decline and global competition intensify, we help sustain local jobs and technical skills, contributing to regional growth.

By strengthening local industry and fostering an environment where people and technology grow together, we aim to advance Japan’s manufacturing for the future.